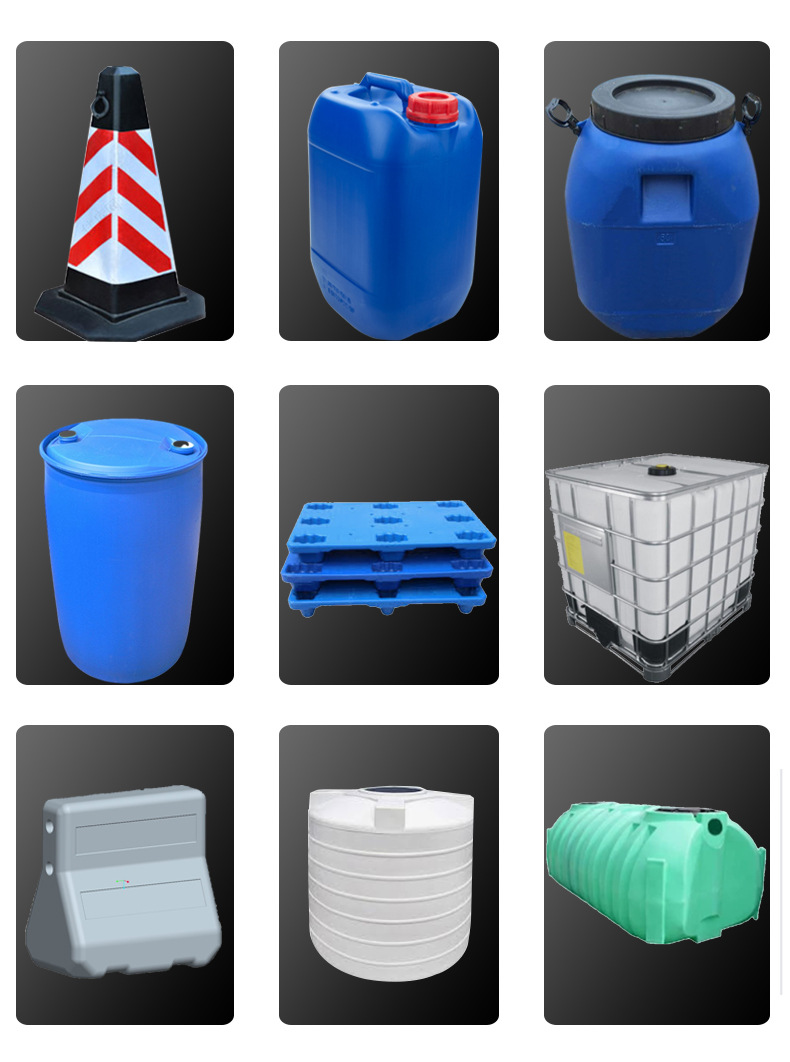

SX series hollow blow molding machine is a blow molding machine developed for large hollow products such as 50L-2000L civil barrels, water storage tanks, septic tanks, etc. The advantage of this series of blow molding machines is that they can process high molecular weight polyethylene and are light in weight. Under the premise of similar products, the strength is higher than similar products. This series of hollow blow molding machines can be equipped with 2-5 layers of composite storage die heads according to the requirements of different products. product features:

product features:

1. Control system: The operation panel uses a 5.7-inch Chinese man-machine interface touch screen, and all actions, parameter settings, monitoring, product counting, wall thickness control and other visual operations are used. Self-judgment and display of equipment failure, simple operation. Imported Japanese Mitsubishi PLC programmable controller has the function of process parameter storage and adjustment, fast response, accurate positioning, and high stability of the system in operation.

2. Hydraulic system: imported hydraulic valves, seals, electro-hydraulic proportional control. It has the characteristics of stability and reliability, accurate action, long service life and fast response.

3. Extrusion system: adopts hard-tooth surface reduction gearbox and Japan imported Mitsubishi frequency converter, which has the characteristics of screw frequency conversion speed regulation, low noise, strong power, stable speed, long service life and energy saving; mixing screw, raw material adaptability Wider, better plasticizing quality, heating barrel and aluminum alloy heater, high efficiency and energy saving.

4. Die head system: adopts center shot material storage cylinder type die head, horizontal bar shot, high stability. The "first in, first out" material storage head has a reasonable and reliable structure.

5. Mold opening and closing system: pneumatic single-cylinder slide rail, fast and stable, four template, high-precision linear guide, hydraulic double-cylinder two-way mold opening and closing.

6. Type control system: optional Japanese MOOG and domestic 10 to 100 point wall thickness control system

7. Blowing system: standard bottom blowing, side blowing and up blowing are optional.

8. Mould cutting knife: standard pneumatic mould cutting knife, fast and standard.

9. Safety system: Equipped with mold clamping protection device and light curtain sensor to ensure the safety of equipment and operators.

10. Electrical components: select international high-tech products.